Fossey Mine

History

Aberfoyle Limited, and later Western Metals Resources Ltd, operated the world-class Hellyer underground mine near Waratah in western Tasmania. The mine was opened in 1989 on a blind ore body discovered in 1983 by modern exploration techniques. The ore was concentrated on site, with the concentrates railed to Burnie for shipment.

Recently (2011) the Hellyer mine was re-opened with mining activites in the Fossey deposit.

Question

How hard is it to get good radio coverage down a 1500m escarpment covered with dense Tasmanian West Coast rain forest?

Answer

Very... The area around Fossey is carpeted with a thick dense forest of Myrtle, Black-wood, Gum, Acacias and anything else you can think of, all of which provide spectacular views but soak up radio signals like a sponge.

To overcome those difficulties the original radio system used two VHF high band multi-channel repeater systems. One on the surface mounted on the Mill roof, the other just outside the mine portal, both linked by a fibre optic cable to ensure a reliable link between the two.

The system worked quite well but there where big holes in coverage along the haul road, noisy communications around the portal which could be minor or major depending on the day and an annoying key-up problem.

Early 2011 a fire had taken out the fibre link which highlighted a safety issue with the whole system during the fire season.

With the need for better coverage and a backup for the fibre link we where asked to see what improvements could be made. As a first step a site survey was conducted to assess the original installation and ascertain the extent of the problem. It was clear the surface system needed to be moved. Two subsequent surveys where done before settling on the new location (Roller Hill) for the surface repeaters. After meeting with management to nail down exactly what was wanted operationally, a proposal was put and agreement made to reconfigure the new system for five channels accessible site wide.

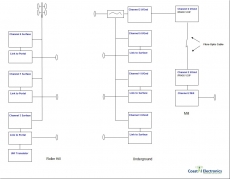

- Channel One - Underground operations

- Channel Two - Secondary underground and back-fill with the optic fiber link to the surface

- Channel Three - Surface operations with underground access and translated on UHF CH 21

- Channel Four - Line of site (but incorporated in Emergency broadcast system)

- Channel Five - Emergency (broadcast on all channels)

Each of the surface repeaters - channels 1, 3, & 5 where to be RF linked with channel 2 utilising the fibre optic link. All mobiles would vote between underground and surface, removing the need to continually change channels.

Roller Hill

The mine extended a small passing bay on Roller Hill and placed a shipping container there to house the repeaters. We erected a three section winch-up mast obtained from FLIGHT BROTHERS in Adelaide on which to mount the antenna system. These guys make just the best product, beautifully constructed and finished, complete with guys, turn-buckles, thimbles... the lot, really good

The antenna system consisted of an RFI BA-40 Binary Array, three side mounted dipoles for the links and two phased side mounted dipoles for the UHF translator.

Inside we installed three VERTEX VXR9000 VHF repeaters. Installed also where 4 GME TX3820 transceivers three for the links to the underground portal, and the other for the UHF Translator. To control audio and emergency functions an OMNITRONICS DSRI was used because of its versatility and ease of operation.

We used an RFI TP1317-1612-11 as a repeater combiner which gave split transmit/receive feeders to the Binary Array antennas.

The system is powered by an IMARK 5020RM 240V AC - 13.8V DC 20 Amp Regulated Power Supply with 200 ah of Battery Back-Up

The big day when everything was powered up and operational was filled with a little trepidation, we had gone to a lot of trouble to get this far, if it didn't perform we would be dead meat... Fortunately everything exceeded expectations, signals everywhere where perfect and at the portal we had enough level to allow for 20dB of path fade, it was a very good day!

The Portal

The portal installation should have been pretty straight forward, with the only concern being the fact that the installation was located hard up against an almost vertical escarpment. The operating system is a five channel RF Technologies 150 series repeater system, utilising an OMNITRONICS IPR400 VOIP unit to route communications via a fibre optic cable to the mill, and a VARIS SmartCom head-end to take care of the underground leaky feeder system. Having pre-configured a new OMNITRONICS DSRI audio bridge in the workshop meant that the whole system was off air for only about ten minutes, however during the configuration stage we discovered that a couple of the RF technology modules where faulty in that audio levels and squelch configurations where not what they should have been and one receiver was quite deaf. We took all but channel one off air and carried out alignments on all other channel modules, then re-connected the DSRI... worked beautifully except the VOIP system was unstable.

We installed the VHF link radios (GME TX3820V), and were overjoyed to find the signals from Roller Hill where as expected -77dBm. A huge relief nonetheless. The VOIP system was removed to the workshop for testing and found that it contained very old firmware which once updated, reconfigured and installed worked as it should...

All in all a great project with great results all carried out in some of the most spectacular country side you could wish to see...